The MultiScan MS5800 is a multi-technology system offering these technologies:

- Eddy Current

- Magnetic Flux Leakage

- Remote Field

- IRIS Ultrasound

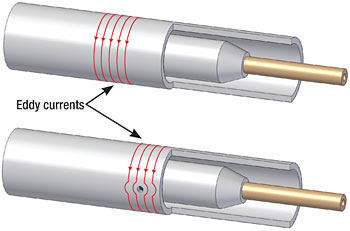

- Tube Inspection with Eddy Current Testing (ECT)

- Tube Inspection with Internal Rotating Inspection System (IRIS) for Ferrous and Nonferrous Materials

- Tube Inspection with Remote Field Testing (RFT)

- Tube Inspection with Near Field Testing (NFT)

- Tube Inspection with Magnetic Flux Leakage (MFL)

MS 5800E

Tube Inspection with Eddy Current Testing (ECT)

- Condensers

- Feedwater heaters

- Heat exchangers

- Air conditioners

Eddy current testing is a noncontact method used to inspect nonferromagnetic tubing. This technique is suitable for detecting and sizing metal discontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks in nonferrous materials.

- Two coils are excited with an electrical current, producing a magnetic field around them. The magnetic fields penetrate the tube material and generate opposing alternating currents in the material. These currents are called eddy currents.

- Any defects that change the eddy current flow also change the impedance of the coils in the probe.

- These changes in the impedance of the coils are measured and used to detect defects in the tube.

MultiScan MS 5800E Key Features

- Four simultaneous frequencies per input.

This feature allows for inspection speeds up to 2 m/s with four frequencies on absolute and differential channels, without signal distortion. - Electronic probe balancing.

No separate external reference probe is required for absolute channel operation. - 4 ECT inputs and up to 64 multiplexed channels.

The MultiScan™ MS 5800E can support a large number of ECT channels to perform array probe inspections. Compared to single-channel inspection, the array probe technology allows for faster and easier surface coverage.

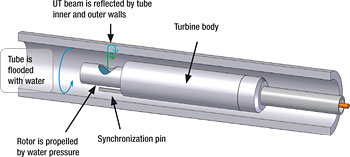

MS 5800U

Tube Inspection with an Internal Rotating Inspection System (IRIS) for Ferrous and Nonferrous Materials

- Boilers

- Feedwater heaters

- Air coolers

- Heat exchangers

The ultrasonic IRIS option is used to inspect a wide range of materials, including ferrous, nonferrous, and nonmetallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts. Olympus digital IRIS inspection technology is used extensively as a prove-up technique for remote field testing, magnetic flux leakage, and eddy current inspections.

MultiScan MS 5800U (IRIS) Key Features

- Setup wizard

Simplifies equipment calibration for different tube diameters and materials. The wizard also generates the reporting code for the inspection. - Real-time gain and gate controls

UT settings can be modified during the C-scan acquisition for quick optimization of signal detection. - Real-time and continuous color C-scans

Reduces missed flaws with C-scan displays. To enhance the quality and appearance of your reports, include color maps and cross-section views of defects. - Full tube-length recording

Used to analyze data off-line, and to assess results with customers.

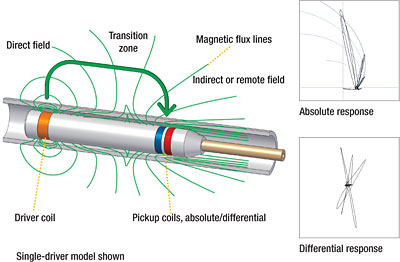

MS 5800R

Tube Inspection with Remote Field Testing (RFT)

- Boilers

- Feedwater heaters

- Carbon steel heat exchangers

Remote field testing (RFT) is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferritic stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defect

亚测(上海)仪器科技有限公司是奥林巴斯中国区域一级代理商,现货供应27MG超声波测厚仪、45MG超声波测厚仪、38DL PLUS超声测厚仪、Magna-Mike8600测厚仪、EPOCH LT超声波探伤仪、EPOCH LTC超声波探伤仪、EPOCH 600超声波探伤仪、EPOCH 650超声波探伤仪、EPOCH XT超声波探伤仪、EPOCH 1000超声探伤仪、OmniScan SX相控阵探伤仪以及NORTEC 600涡流探伤仪、NORTEC 2000D涡流探伤仪等系列产品,欢迎广大新老客户前来咨询!

通过认证

通过认证